Raw Material Handling

Ensure a seamless raw material handling process with our efficient…

Ensure a seamless raw material handling process with our efficient…

Optimize steel heating processes with our advanced induction heating facilities…

Our cutting facilities offer precision hot shearing and bar cutting…

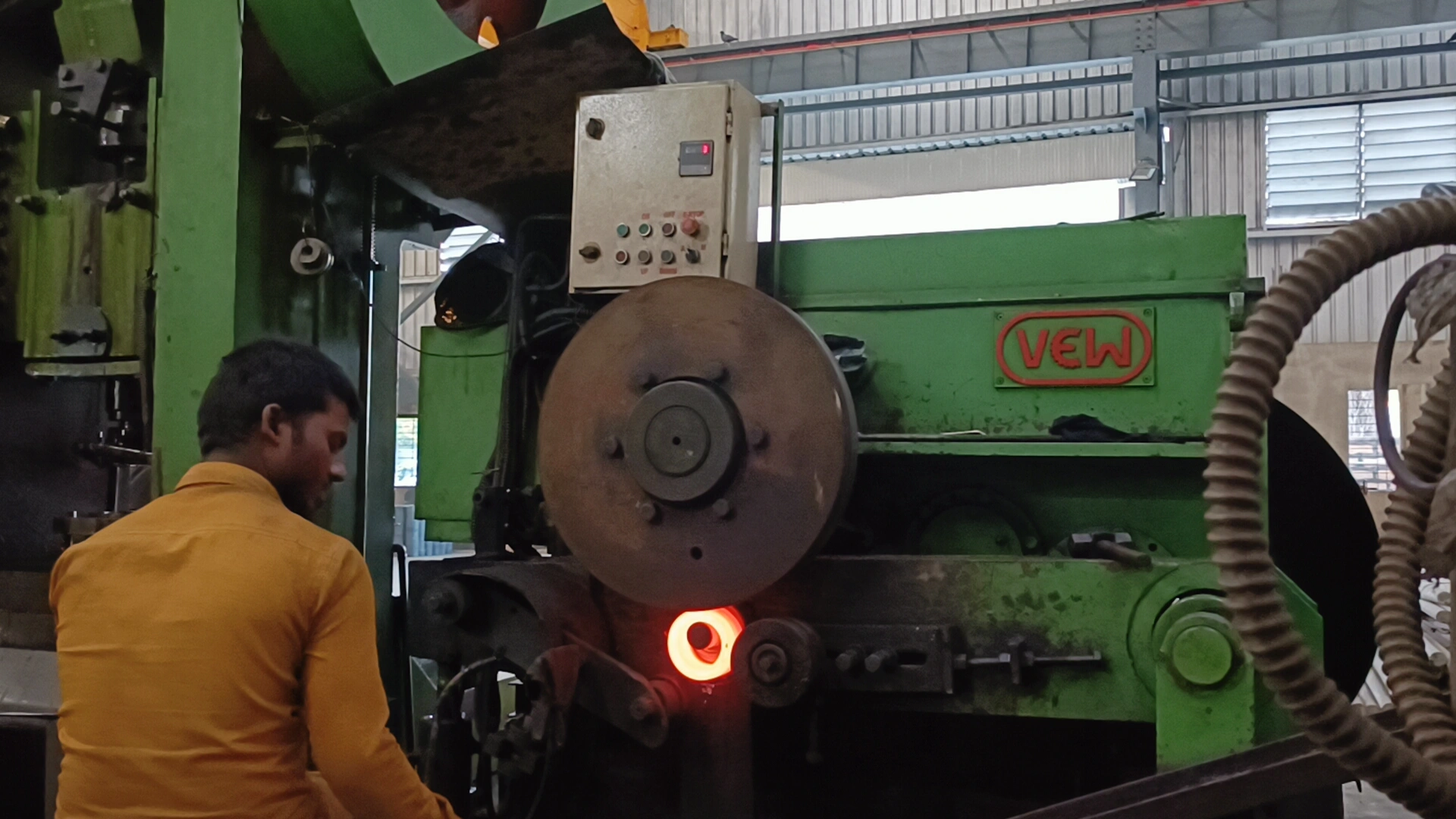

We provide state-of-the-art forging facilities with advanced presses and ring…

Enhance steel durability with our heat treatment solutions, including annealing,…

Achieve high precision with our CNC finishing services, delivering expertly…

13 min Read

The aerospace industry is one of the most demanding sectors when it comes to precision, strength, and reliability. The parts used in aircraft, satellites, and other aerospace components must adhere to strict standards and undergo rigorous testing to ensure their safety and performance. Steel forging has long been a key manufacturing process for producing components that meet these high standards. As technology advances and the aerospace industry evolves, the future of steel forging is poised for significant transformation. This article explores the current state of steel forging in aerospace and looks ahead at the emerging trends and innovations shaping the industry.

Steel forging is essential for creating critical components that require high strength-to-weight ratios, durability, and resistance to extreme temperatures and pressures. Forging is a manufacturing process where metal is heated and shaped by applying pressure, resulting in components that are denser and stronger than those made using other processes like casting or machining.

In aerospace, steel forging is used for a wide range of applications, including engine components, structural elements, landing gear, and more. These parts are subjected to extreme conditions, such as high-speed impacts, high temperatures, and continuous stress, making the quality of the forged steel critical to ensuring the safety and performance of the aircraft.

Forging can be classified into different categories such as open-die forging, closed-die forging, and rolled ring forging. These methods are specifically tailored to meet the needs of different aerospace components, each having its own unique challenges and advantages. The high-strength components created through these processes are used in a variety of crucial aerospace applications like turbine blades, aircraft structural parts, and bearings.

As the aerospace industry continues to evolve, several key trends are shaping the future of steel forging:

One of the primary drivers of innovation in steel forging for aerospace is the development of advanced forging techniques. These methods allow for greater precision, stronger parts, and reduced production costs. Some of the most promising techniques include:

While steel forging offers many benefits to the aerospace industry, there are several challenges that manufacturers must overcome to continue meeting the demands of the sector:

The future of steel forging in aerospace is bright, with new advancements and technologies shaping the way components are designed and produced. As the industry continues to grow, steel forging will play a vital role in creating the lightweight, durable, and high-performance components needed for the next generation of aircraft and aerospace systems. Key areas of focus will include:

Steel forging will remain a critical process in the aerospace industry for the foreseeable future, but the techniques and technologies used to produce these components will continue to evolve. As the demand for high-performance, durable, and lightweight parts grows, the aerospace sector will rely on innovations in forging to meet these challenges. By embracing new technologies, advanced materials, and more sustainable practices, steel forging will play a key role in the continued success and growth of the aerospace industry.

As we look to the future, it is clear that steel forging will remain a cornerstone of aerospace manufacturing. However, its evolution will continue to be shaped by technological advancements and the ongoing need for precision, performance, and sustainability. Active Steel Forge and other industry leaders will play a key role in driving these changes, ensuring that aerospace components are produced with the highest standards of quality and efficiency.

Get in touch with our experts today