Raw Material Handling

Ensure a seamless raw material handling process with our efficient…

Building a strong foundation for high-quality manufacturing.

Careful inspection and sorting of raw materials ensure uniformity and eliminate defects before production begins.

Efficient storage and handling minimize material wastage, optimizing costs and promoting sustainability in the manufacturing process.

Streamlined handling reduces delays and ensures raw materials are always production-ready, enhancing workflow efficiency.

Ensuring quality and efficiency from the very start.

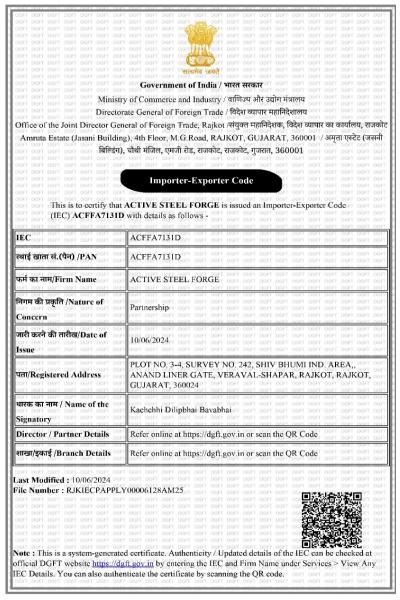

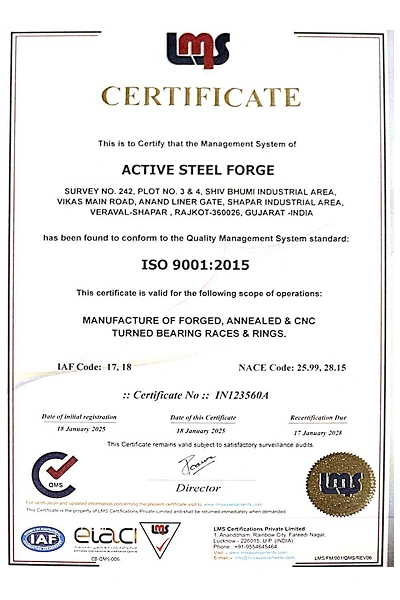

At Active Steel Forge, our raw material handling operations are designed to meet the most demanding industry standards, ensuring a seamless transition from raw materials to finished components.

All raw materials undergo a rigorous inspection process to ensure they meet required specifications and quality standards.

Materials are stored in a climate-controlled environment to prevent corrosion, deformation, or contamination.

State-of-the-art equipment, including automated cranes and conveyors, ensures precise and damage-free handling of raw materials.

Raw materials are cut, cleaned, and prepared to exact specifications before entering the production process.

Experience our state-of-the-art facility from anywhere

Team Size

Annual Capacity

Established

1

We source premium materials for superior quality.

2

Each material batch undergoes rigorous testing for composition, strength, and key properties.

3

Materials are categorized, labeled, and stored systematically for easy identification and retrieval.

4

Automated systems transfer raw materials to production zones, ensuring precision and safety.

State-of-the-art systems for precision and efficiency.

At Active Steel Forge, we leverage cutting-edge technology to ensure seamless material handling and preparation for production.

Custom solutions tailored to your specific manufacturing needs.

At Active Steel Forge, we understand that every project has unique material requirements. That’s why we focus on creating tailored handling processes that align with your goals.

Performance

A proven track record of efficiency and reliability.

Material Accuracy

Tons Handled Annually

Waste Reduction

Handling Operations

Get in touch with our experts today